Unlocking Innovation with Rapid Prototype Technology in Metal Fabrication

In today's fast-paced industrial landscape, innovation and speed are critical determinants of success. For metal fabricators, adopting cutting-edge techniques such as rapid prototype manufacturing has revolutionized traditional workflows, enabling companies to deliver superior products faster, more efficiently, and with exceptional precision. At Deep Mould, we are committed to integrating rapid prototype solutions into our metal fabrication process, driving forward the boundaries of what is possible in the industry. This comprehensive guide explores how rapid prototype technology is transforming the world of metal fabricating and why it is essential for staying ahead of the competition.

What Is Rapid Prototype Technology in Metal Fabrication?

Rapid prototype technology refers to a collection of manufacturing processes aimed at quickly producing scale models or functional prototypes of parts and products. In metal fabrication, this involves techniques that allow for the fast creation of detailed, accurate metal parts for testing, evaluation, and refinement before mass production. The cornerstone of rapid prototype is its ability to drastically reduce lead times from concept to tangible model, facilitating faster iterations, cost savings, and superior design validation.

Core Techniques Supporting Rapid Prototype in Metal Fabrication

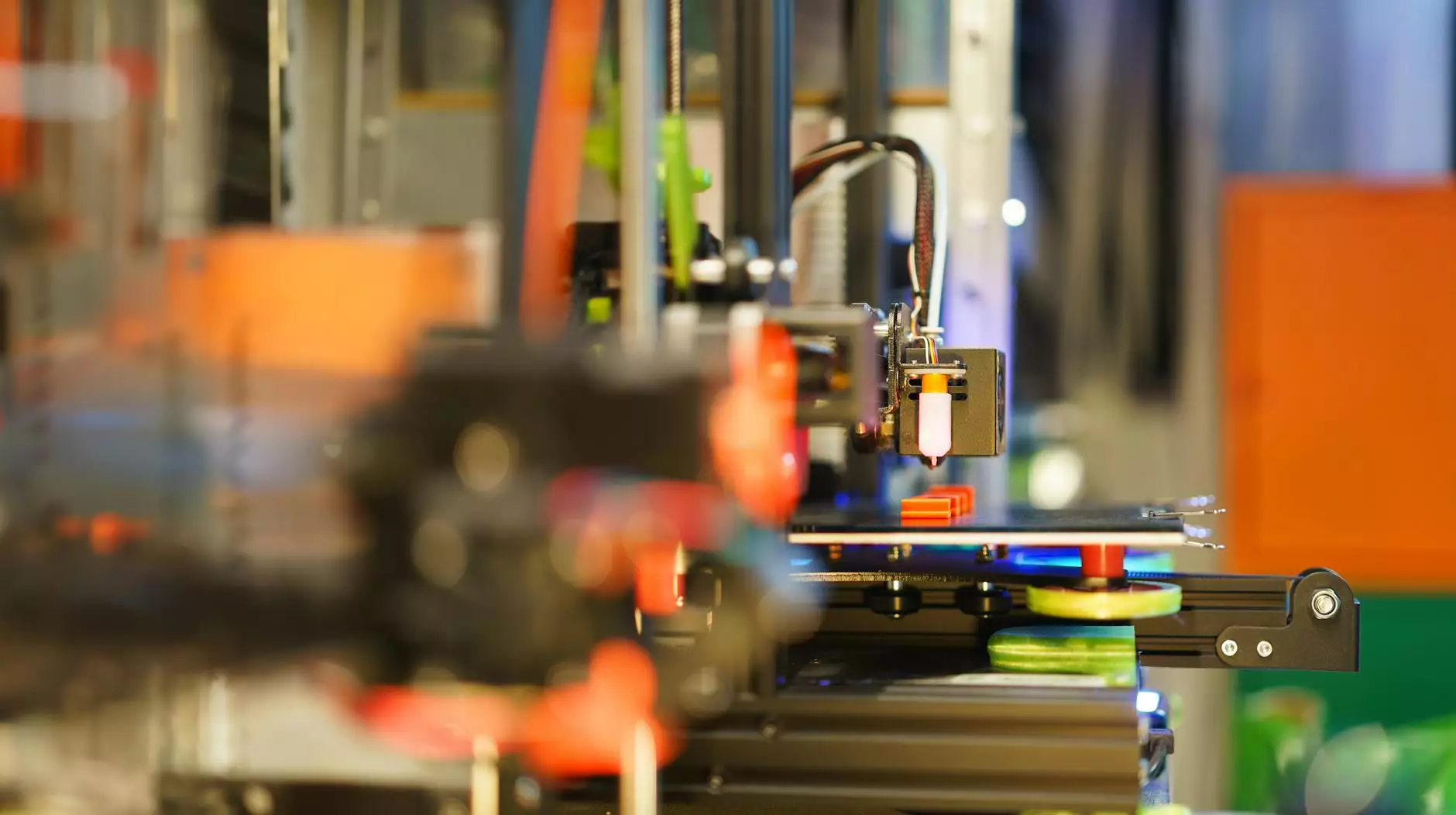

- Selective Laser Melting (SLM) — A form of 3D printing that uses a high-powered laser to fuse metal powders layer by layer, creating complex geometries with high precision.

- Direct Metal Laser Sintering (DMLS) — Similar to SLM, DMLS is used for rapid prototyping of durable metal parts with excellent mechanical properties.

- CNC Machining — Computer-controlled milling and turning that allows for fast, accurate production of prototypes directly from CAD files.

- Investment Casting — For producing prototypes that resemble final production parts with high accuracy, especially for metal parts requiring surface finish and durability.

Advantages of Implementing Rapid Prototype in Metal Fabrication

Integrating rapid prototype methods into your metal fabrication workflow provides myriad benefits that can significantly enhance your product development cycle and market competitiveness:

1. Accelerated Product Development Timeline

By reducing the time needed to produce prototypes, rapid prototype technology enables teams to validate designs, identify flaws, and iterate swiftly. What previously took weeks can now be accomplished in days or even hours, allowing companies to bring products to market faster than ever before.

2. Cost Reduction and Resource Optimization

Traditional prototyping methods often involve expensive molds and tooling, resulting in high upfront costs. Rapid prototype techniques like metal 3D printing minimize these costs by avoiding the need for costly tooling during early design validation, saving money and reducing material waste.

3. Enhanced Design Flexibility and Innovation

With rapid prototype, designers are empowered to explore complex geometries and intricate features that would be difficult or impossible with conventional manufacturing. This freedom fuels innovation, enabling the creation of highly functional, optimized parts and new product concepts.

4. Improved Product Quality and Functionality

Prototypes created via rapid prototype methods accurately replicate the final product's look, feel, and performance attributes. This fidelity allows for comprehensive testing and validation, ensuring the final product performs as intended.

5. Streamlined Communication with Stakeholders

Having tangible, high-quality prototypes facilitates transparent communication among engineers, designers, investors, and clients, ensuring everyone shares a clear understanding of the project’s direction and expectations.

Deep Mould’s Expertise in Rapid Prototype and Metal Fabrication

At Deep Mould, we specialize in offering advanced rapid prototype solutions tailored specifically for the needs of metal fabricators. Our state-of-the-art facilities and skilled technicians utilize the latest technologies, such as SLM, DMLS, and CNC machining, to deliver high-quality prototypes that align with your project goals.

Our commitment to quality and precision means every rapid prototype we produce embodies durability, intricate detail, and accuracy. We understand the importance of fast turnaround times in today’s competitive environment, which is why our team works diligently to provide expeditious and reliable prototype services to help you maintain your market edge.

How Rapid Prototype in Metal Fabrication Enhances Your Business Strategy

Incorporating Rapid Prototype Throughout Your Product Lifecycle

The integration of rapid prototype techniques into every phase of your product lifecycle — from initial design and proofing to testing and small-batch production — ensures continuity and efficiency. This approach minimizes delays, optimizes resources, and improves overall product quality.

Driving Innovation and Competitive Advantage

By leveraging rapid prototype technology, metal fabricators can experiment with complex designs, test new materials, and refine manufacturing processes without significant financial risk. This fosters a culture of innovation, allowing businesses to develop unique, differentiated products that stand out in the marketplace.

Supporting Just-in-Time Manufacturing and Customization

With the agility provided by rapid prototype methods, companies can implement just-in-time manufacturing strategies, reducing inventory costs and enabling high levels of customization tailored to client specifications. This flexibility is crucial in industries like aerospace, automotive, and medical devices where bespoke solutions are highly valued.

The Future of Rapid Prototype in Metal Fabrication

The evolution of rapid prototype technology continues to reshape the landscape of metal fabrication. Emerging innovations, such as hybrid manufacturing processes combining additive and subtractive techniques, artificial intelligence for optimization, and new materials with enhanced properties, will further accelerate development cycles and allow for even more intricate designs.

Furthermore, the integration of digital twin and Industry 4.0 principles will enable real-time monitoring and adaptive adjustments throughout the prototyping and manufacturing phases, making rapid prototype a cornerstone of next-generation manufacturing ecosystems.

Partnering with Deep Mould for Your Rapid Prototype Needs

Choosing the right partner is vital to maximizing the benefits of rapid prototype in your metal fabrication projects. Deep Mould’s extensive expertise, advanced machinery, and dedicated customer support position us as your ideal collaborator. We work closely with clients to understand their unique requirements, ensuring results that exceed expectations.

Our comprehensive range of rapid prototype services includes:

- High-precision 3D printing of metal prototypes

- CNC machining for detailed, functional models

- Investment casting for near-final prototypes

- Post-processing to achieve optimal surface finish and tolerances

- Material selection guidance for durability and performance

Conclusion: Embracing Rapid Prototype for a Smarter, Faster Future

As the demand for faster turnaround times, higher quality products, and innovative designs continues to skyrocket, rapid prototype technology has become indispensable for metal fabricators. It empowers companies to streamline their development processes, reduce costs, and unlock new levels of design possibilities.

Deep Mould stands at the forefront of this technological revolution, dedicated to providing top-tier rapid prototype solutions that accelerate your journey from concept to reality. By embracing rapid prototype methods today, your business can stay competitive, foster innovation, and lead the industry tomorrow.

Take the next step towards manufacturing excellence—partner with Deep Mould, and let us help you transform your ideas into tangible, high-quality metal prototypes with unmatched speed and precision.