Embracing Precision: The Role of Precision Injection Molding Suppliers in Modern Manufacturing

The Backbone of Innovative Manufacturing

In today's fast-paced industrial landscape, the demand for high-quality, precise manufacturing processes is at an all-time high. Among the myriad of techniques that manufacturers employ, precision injection molding stands out due to its ability to produce complex parts with tight tolerances at scale. As a precision injection molding supplier, Deep Mould shines as a beacon of reliability and excellence in this sector.

This article delves into the intricacies of precision injection molding, exploring its benefits, applications, and why choosing the right supplier is essential for your business’s success.

Understanding Precision Injection Molding

At its core, precision injection molding is a manufacturing process where molten material—commonly thermoplastics or thermosets—is injected into a mold to form specific shapes. Here are the essential components that make this process efficient and effective:

- Mold Design: The first step involves creating a high-precision mold that can withstand repetitive use while ensuring that the injected material fills every nook and cranny, optimizing dimensional accuracy.

- Material Selection: The type of material plays a significant role in the end-product quality. Common choices include ABS, polycarbonate, and nylon.

- Injection Process: This step requires advanced machinery capable of maintaining consistent temperatures and pressures to ensure uniform material flow into the mold.

- Cooling and Ejection: Post-injection, the part must cool adequately before being ejected from the mold, minimizing defects related to warpage or dimensional inaccuracy.

Advantages of Precision Injection Molding

Choosing a precision injection molding supplier offers numerous advantages. Here are some of the most significant benefits that manufacturers can leverage:

1. Cost Efficiency

One of the primary advantages of precision injection molding is its cost-effectiveness, especially for large production runs. The ability to produce large volumes with minimal labor and material waste significantly lowers the per-unit cost.

2. High Precision and Consistency

The high precision of the molding process ensures that each part produced is consistent in quality and dimension, which is critical in industries where minor discrepancies can lead to failures, such as automotive and aerospace.

3. Design Flexibility

Whether it’s intricate designs or complex geometries, precision injection molding accommodates a vast range of shapes and sizes, allowing designers to push the boundaries of creativity while ensuring functionality.

4. Quick Turnaround Times

With advanced machinery and streamlined processes, precision injection molding suppliers can significantly reduce production lead times, enabling businesses to respond quickly to market demands.

Applications of Precision Injection Molding

The applications of precision injection molding span various industries, showcasing its versatility. Here are several key sectors that heavily rely on this manufacturing process:

- Aerospace: Precision components are crucial for performance and safety in the aerospace sector.

- Automotive: Engine components, dashboards, and electronic housings often undergo precision injection molding.

- Medical Devices: Time-sensitive and critical applications in healthcare depend on the reliability of molded components.

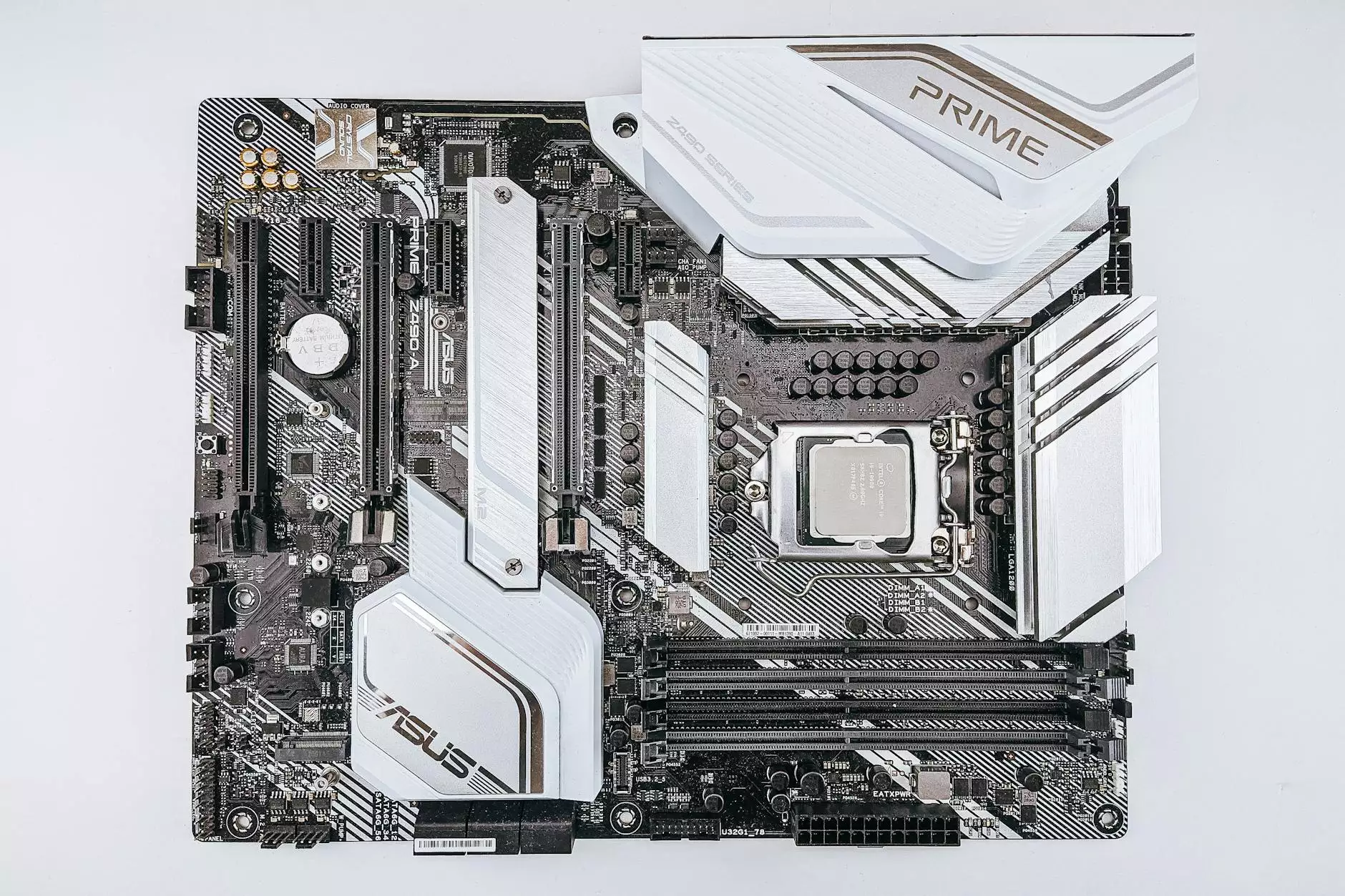

- Consumer Products: Everyday items, from containers to electronics casings, benefit from this manufacturing technology.

Choosing the Right Precision Injection Molding Supplier

Selecting the right precision injection molding supplier is crucial for achieving optimal results. Here’s what to consider during your selection process:

- Experience and Expertise: Look for suppliers with a proven track record in precision injection molding and relevant industry experience.

- Quality Assurance: Ensure that the supplier adheres to robust quality control measures, including ISO certification.

- Technological Capabilities: Advanced technology and machinery are key indicators of a supplier’s ability to deliver precision and efficiency.

- Custom Solutions: The best suppliers can offer customized services tailored to your specific requirements.

Deep Mould: Your Trusted Precision Injection Molding Supplier

As an esteemed precision injection molding supplier, Deep Mould is committed to delivering unparalleled quality and service in every project. Our investment in cutting-edge technology and a highly skilled workforce enables us to meet the diverse needs of our clients across various industries. Here’s why partnering with Deep Mould can elevate your manufacturing processes:

Commitment to Quality

Deep Mould operates under stringent quality assurance protocols, ensuring that every part produced aligns with the highest industry standards. Our state-of-the-art quality testing facilities allow us to identify and rectify potential issues before they affect production.

Innovative Solutions

We pride ourselves on our ability to provide innovative solutions to complex manufacturing challenges. Whether it's material selection, design adjustments, or production efficiency, we work closely with our clients to deliver effective outcomes.

Customer-Centric Approach

At Deep Mould, our clients are at the heart of everything we do. We prioritize open communication and collaborative partnerships to understand and meet their needs completely.

Future Trends in Precision Injection Molding

The landscape of precision injection molding is continuously evolving. As technology advances, several trends are shaping the future of this manufacturing process:

- Automated Technologies: Increased automation in the injection molding process enhances efficiency and reduces labor costs.

- Smart Manufacturing: The integration of IoT (Internet of Things) enables real-time monitoring and predictive maintenance, improving reliability.

- Sustainable Practices: Eco-friendly materials and recycling methods are becoming standard as companies prioritize sustainability.

- Advanced Materials: Development in materials, including bioplastics and composites, are broadening the scope of applications.

Partner with Deep Mould Today

When it comes to precision injection molding, choosing the right supplier is pivotal. With Deep Mould, you gain a partner that prioritizes your success through quality, innovation, and service. Contact us today to learn more about how we can meet your precision injection molding needs and contribute to your business's growth.